Industrial Automation

SoMachine PLC programming

We have experience in Schneider Electric's SoMachine software. SoMachine is CoDeSys V4.1 with built in DTM for configuration or commissioning of devices. It also adds Viejo Schneider's HMI software. The integration allows you to share tags between PLC and HMI. Offering 100% flexibility and optimization, Schneider Electric's SoMachine software allows the OEM to design, commission and service machines in a single software suite, resulting in a significant competitive advantage.

We can undertake small PLC projects at rates much lower than that of the large companies. We can provide your project with immediate support for a day, a week, a month or longer to support your project requirements.

Netcommander the small scale Scada alternative

Netcommander is our small scale monitoring and control product.

It is very adaptable and has been used for projects including industrial fridge, temperature and environment monitoring to industrial machine monitoring. We have supplied to sectors including the military, banking and industry.

In many cases, these projects could have used a Scada system, but were simply to small to merit the cost of installing Scada. Netcommander mostly uses 3rd party sensors to monitor the environment condition. However, in a number of instances, where 3rd party sensors were not available, we have developed our own.

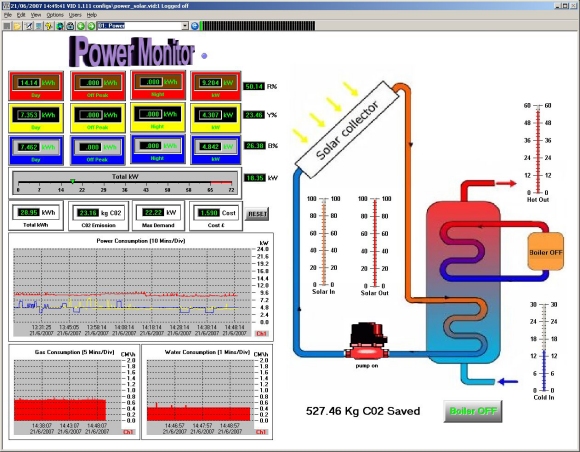

The Netcommander offering is completed with its very own Virtual Instrumentation Desktop (VID). This is fully customizable and can show the process with the real time data being monitored in an easy to understand graphical format. Set points and limits can be programmed in to the system to alert if any of the real time data goes outside its operational limits.

The Netcommander’s Virtual Instrumentation Desktop

SCADA

SCADA systems use multiple software and hardware elements that allow industrial organizations to:

-

Monitor, gather, and process data

-

Interact with and control machines and devices such as valves, pumps, motors, and more, which are connected through HMI (human-machine interface) software

-

Record events into a log file

In basic SCADA architectures, information from sensors or manual inputs are sent to PLCs (programmable logic controllers) or RTUs (remote terminal units), which then send that information to computers with SCADA software. SCADA software analyzes and displays the data in order to help operators and other workers to reduce waste and improve efficiency in the manufacturing process.

Effective SCADA systems can result in significant savings of time and money. Numerous case studies have been published highlighting the benefits and savings of using a modern SCADA software solution such as Ignition.